Payment Type:T/T,Others

Incoterm:FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery

Transportation:Ocean,Land,Air,Express,Others

Port:Guangzhou,Shenzhen,Ningbo

$0.0510000-99999Piece/Pieces

$0.1≥100000Piece/Pieces

Model No.: D12*18mm

Brand: YB

Place Of Origin: China

Species: Permanent

Composition: Ferrite Magnet, Rare Earth Magnet, Neodymium Magnet, Plastic Magnet, Ndfeb Magnet, Alnico Magnet, Rubber Magnet

Shape: Sheet, Pot / Cup Shape, Bar, Stick, Strip, Cup Shape, Block, Coil, Ball

Application: Moto Magnet

Tolerance: ±1%

Processing Service: Bending, Welding, Decoiling, Cutting, Punching, Moulding

Product Name: Ferrite Magnet Cylinder

Material Grade: Y25,Y30,Y30BH,Y35

Working Temperature: -40-250℃

Color: original color

Certificates: CE,ROHS,MSDS

Quality Certificates: ISO9001

Delivery Time: 7-15 days

Packaging: carton package and then packed in pallet

Productivity: 5000000pcs per month

Transportation: Ocean,Land,Air,Express,Others

Place of Origin: China

Supply Ability: 5000000pcs per month

Certificate: ISO9001

HS Code: 8505190090

Port: Guangzhou,Shenzhen,Ningbo

Payment Type: T/T,Others

Incoterm: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery

What's ferrite magnet? A ferrite magnet is a type of Permanent Magnet made from a ceramic material called ferrite. It is composed of iron oxide and one or more other metallic elements such as barium, strontium, or lead. Ferrite magnets are relatively inexpensive and have high magnetic properties, making them widely used in various applications such as speakers, motors, and sensors. They are also resistant to demagnetization, corrosion, and high temperatures. What's Ferrite Magnet Rotor? A Ferrite Magnet Rotor is a type of rotor used in electric motors, generators, and other electromagnetic devices. It is made up of a series of anisotropic ferrite magnets that are made from a type of ceramic material called ferrite. These magnets are arranged in a specific pattern around the rotor, which creates a magnetic field when the rotor spins. Ferrite Magnet Rotors are known for their high magnetic strength, low cost, and durability, making them a popular choice for a variety of industrial and consumer applications.

Different types of magnetic rotor

As an AI language model, I don't have the ability to generate visual content. However, I can provide you with a list of different types of magnetic rotors:

2. Induction rotor

3. Synchronous rotor

4. Switched reluctance rotor

5. Brushless DC (BLDC) rotor

6. Doubly-fed induction rotor

7. Wound rotor

8. Magnetic levitation rotor

9. Homopolar rotor

10. Halbach rotor.

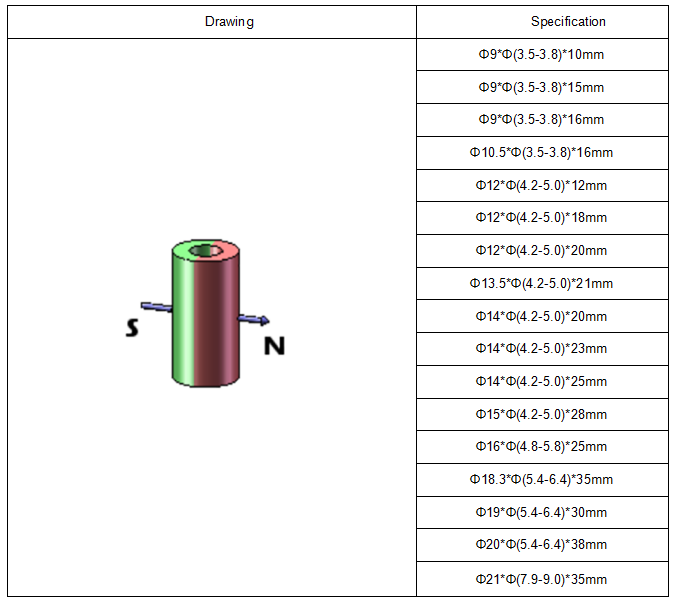

The material grade for ferrite magnet rotor The available sizes for Anisotropic Ferrite Magnet

Sintering: The pressed product is then sintered in a furnace at a high temperature. This process helps to fuse the particles together and create a solid structure.

Machining: The sintered product is then machined to the desired shape and size. This step is critical to ensure that the final product meets the required specifications.

The final step is to magnetize the product using a magnetizing machine. This process aligns the magnetic domains in the material and creates a magnetic field.

The finished product is then inspected for quality and packaged for shipment.

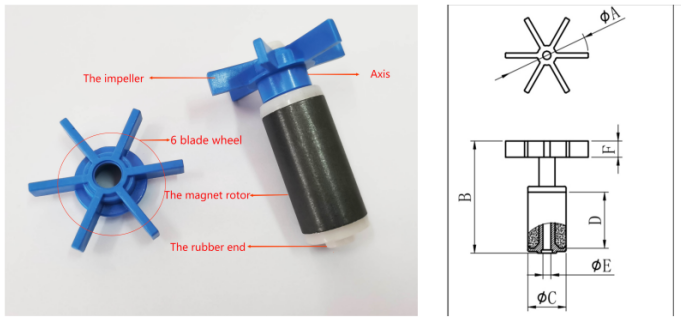

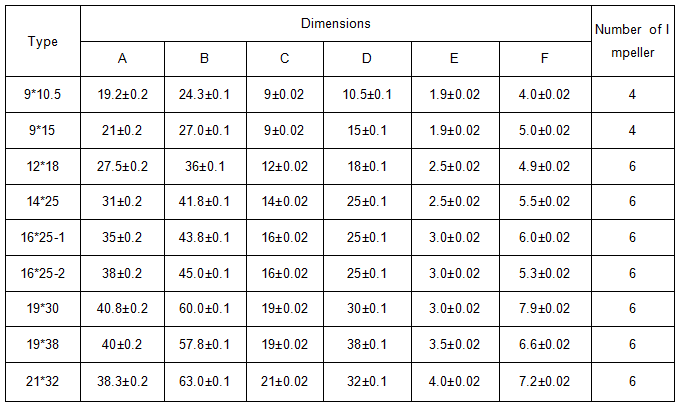

The artwork for Ferrite Magnet Rotor

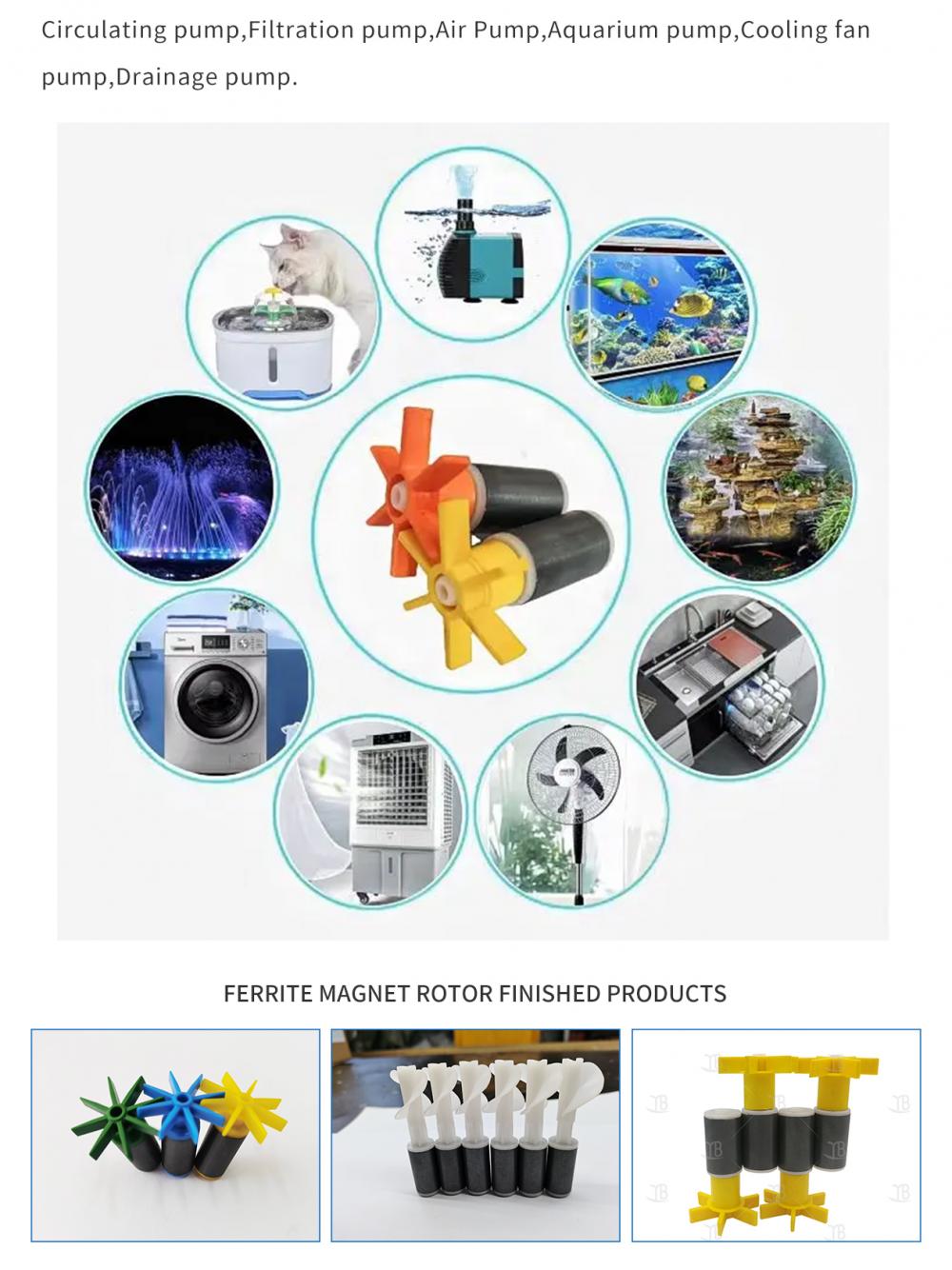

Application: