Payment Type:T/T

Incoterm:FOB,EXW

Min. Order:10000 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Shenzhen,Shanghai,Ningbo

$0.19-0.21 /Piece/Pieces

Model No.: YB-R-19

Brand: Yubang

Place Of Origin: China

Species: Permanent

Composition: Ferrite Magnet

Application: Industrial Magnet

Processing Service: Moulding, Punching, Cutting

Shape And Material: Cylinder ferrite magnet + POM/Nylon impeller

Tolerance: -0.05~-0.02mm

Surface Guass: 1650±50GS

Free Sample: Available

Delivery Time: 8-30 days

Packaging: Carton,pallet,or at request

Productivity: 3 million per month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 3 million per month

Certificate: ISO9001,SGS,MSDS,ROHS,REACH

HS Code: 85051900

Port: Shenzhen,Shanghai,Ningbo

Payment Type: T/T

Incoterm: FOB,EXW

Ferrite Magnet Rotor / D19x30mm Permanent Magnet Rotor

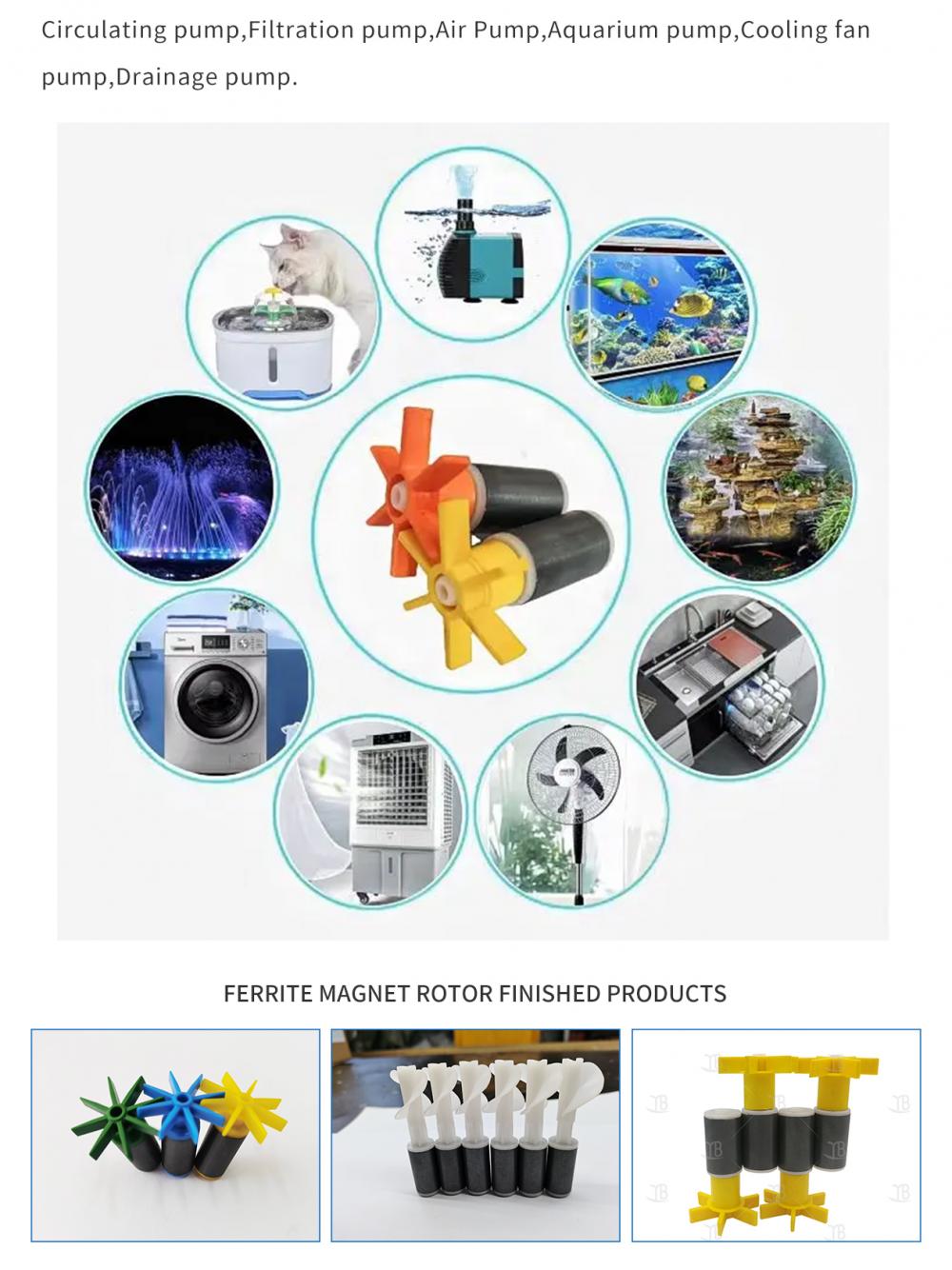

This Cooler Pump Magnet is made of ferrite magnet and POM/Nylon impeller,it is suitable for water pump motor, aquatic submersible pump and various micro water pumps, automobile motor, household appliances, electronic instruments and other industries.

Ferrite magnets, also known as ceramic magnets, are made of iron oxide and strontium or barium carbonate. They are relatively inexpensive and have a low magnetic strength, but they are resistant to corrosion and can withstand high temperatures. They are commonly used in motors, speakers, and refrigerator magnets.

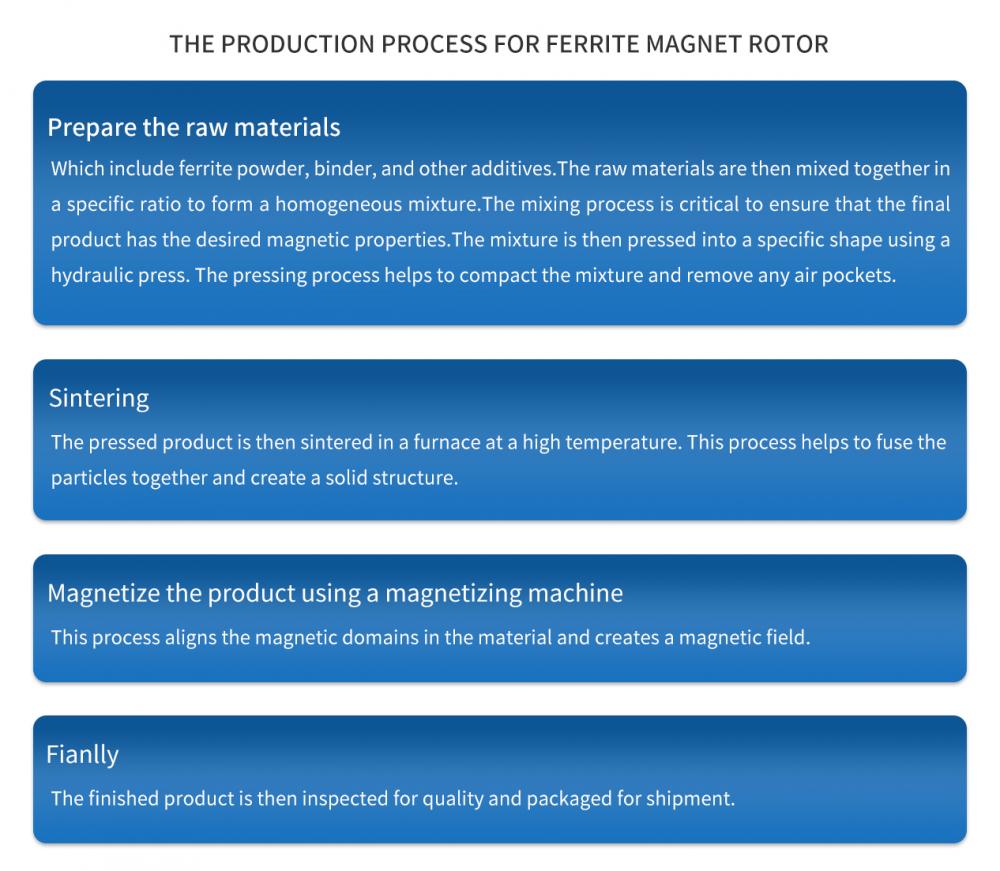

production process of injection moulded Pump Magnet

1. Designing the mold: The first step is to design the mold that will be used to create the pump magnet. The design will typically include the shape, size, and features of the magnet, as well as any necessary cavities or channels for the injection molding process.

2. Preparing the materials: The materials used for injection molding typically include thermoplastics such as nylon, polycarbonate, or polypropylene. These materials are melted down and then injected into the mold.

3. Injection molding: The next step is to inject the melted plastic into the mold. This is typically done using a machine that applies pressure to the plastic and forces it into the mold.

4. Cooling: Once the plastic has been injected into the mold, it needs to cool and solidify. This is typically done by cooling the mold with water or air.

5. Ejecting the magnet: Once the plastic has cooled and solidified, the mold is opened and the pump magnet is ejected. This is typically done using a mechanical ejector system.

6. Finishing: The pump magnet may then undergo additional finishing processes, such as trimming or polishing, to achieve the desired final shape and surface finish.

7. Quality control: Finally, the pump magnet is inspected to ensure that it meets the required quality standards. This may involve visual inspection, dimensional measurement, or other testing methods.

The material grade for ferrite magnet rotor

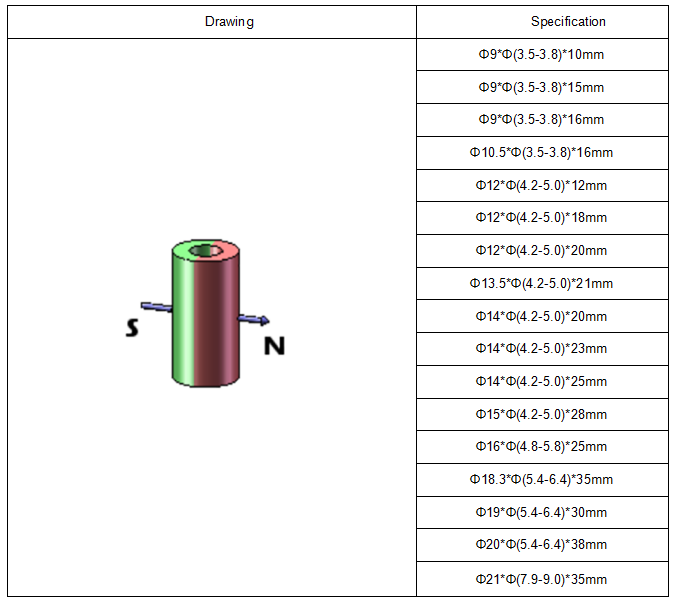

The available sizes for Anisotropic Ferrite Magnet

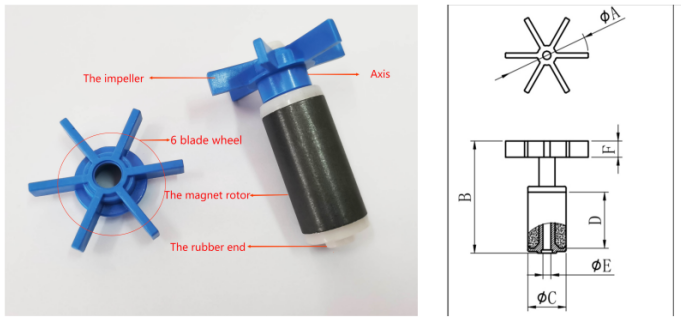

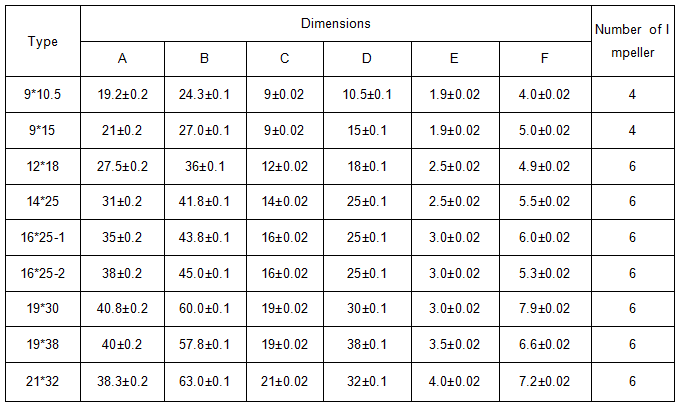

The artwork for Ferrite Magnet Rotor

Ferrite Magnet Rotor made of Anisotropic Ferrite Magnet and Impeller

Overall, electric kilns are an essential tool for pottery and ceramics artists who want to create high-quality pieces. With the right equipment and techniques, artists can achieve beautiful and unique results that are sure to impress.

1) Application Describe to us how and for what purpose the magnet will be used. This will be the basis for all further questions and discussions.

2) Dimensions Describe to us what size of magnet is required,a mechanical drawing will be extremely helpful.

3) Shape What specific shape of magnet is required for your application? Most standard shapes of magnets are rings, blocks, discs, rods, arc, cylinders and segment.

4) Material Several types of magnetic material are available like Ferrite, Neodymium. Depending on the application mentioned above we can identify the best suited material for your application.

5) Grade/Strength The application will determine the strength/grade of magnet you require.

6) Magnetization A magnet can be magnetized through its thickness, length or diameter, depending on its orientation. lt can also be magnetized with multiple poles on the same face of magnet. The purpose of various magnetization pattern is to alter the magnet's strength to best fit an application.