Payment Type:T/T

Incoterm:FOB,CFR,CIF,EXW,DDP

Min. Order:10000 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Guangzhou,Shanghai,Ningbo

$0.07-0.2 /Piece/Pieces

Model No.: YB-R

Brand: YB

Place Of Origin: China

Species: Permanent

Composition: Rare Earth Magnet, Ferrite Magnet

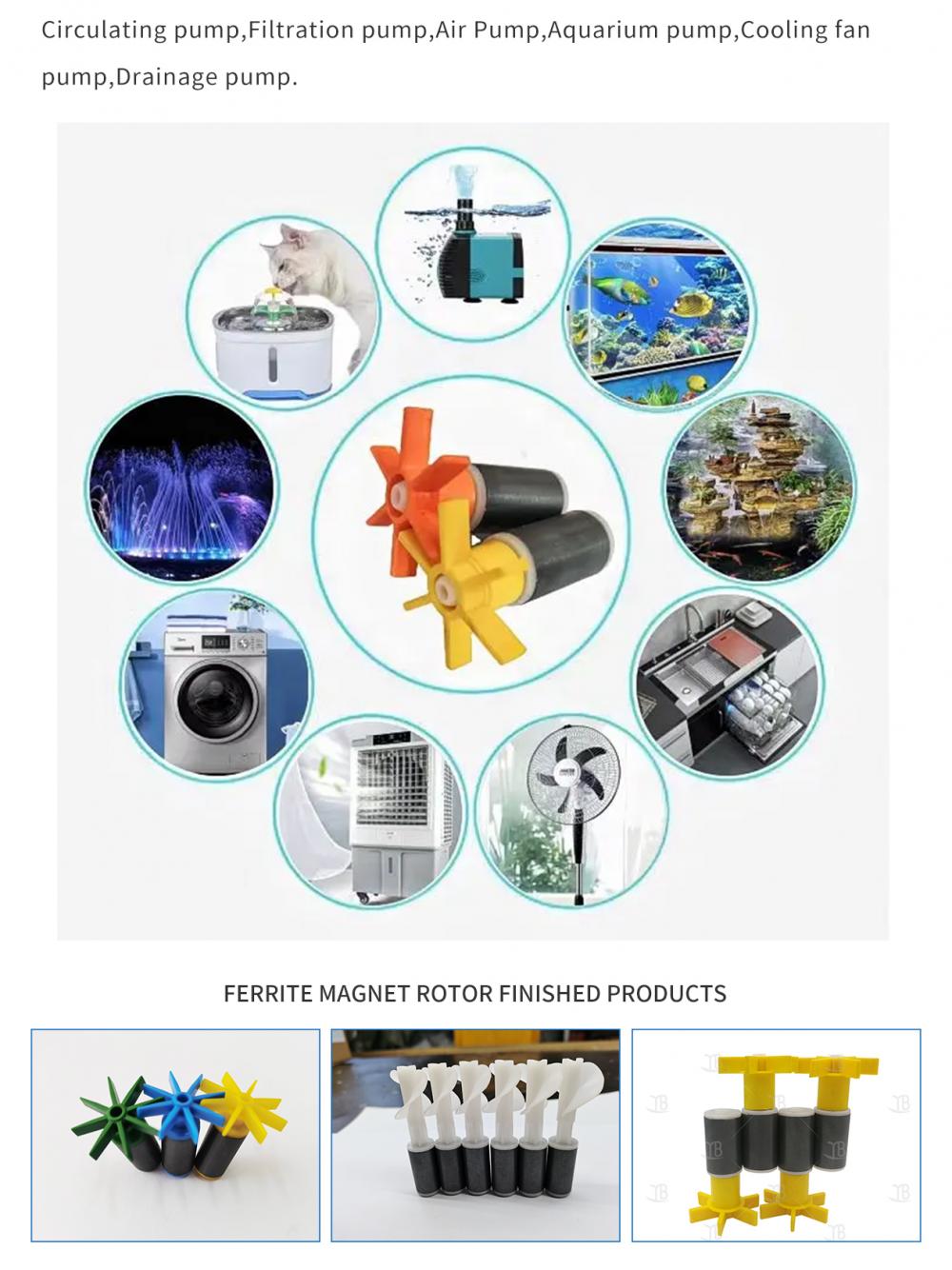

Application: Industrial Magnet

Tolerance: ±1%

Processing Service: Bending, Welding, Decoiling, Cutting, Punching, Moulding

Size: 12*18

Composite: Ferrite magnet, Nylon, POM

Sample: Available

Grade: Y30

Packaging: carton packing, then in wood pallet

Productivity: 10 millions per month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 10 millions per month

Certificate: ISO9001

HS Code: 85051900

Port: Guangzhou,Shanghai,Ningbo

Payment Type: T/T

Incoterm: FOB,CFR,CIF,EXW,DDP

A ferrite magnet rotor is a type of rotor used in electric motors and generators. It is made of a magnetic material called ferrite, which is a ceramic compound consisting of iron oxide (Fe2O3) combined with other metal oxides.

The production of ferrite magnet rotors involves several steps:

1. Raw material preparation: The first step is to prepare the raw materials required for the ferrite magnet. This involves mixing the powdered forms of iron oxide and other metal oxides in specific proportions.

2. Mixing and grinding: The raw materials are mixed together thoroughly to ensure a homogeneous blend. The mixture is then ground into a fine powder to enhance its properties.

3. Compaction: The powdered mixture is compacted using a hydraulic press to form the desired shape of the rotor. The press applies high pressure to the powder, which results in the formation of a solid, dense structure.

4. Sintering: The compacted rotor is then subjected to a sintering process. Sintering involves heating the compacted powder at a high temperature below its melting point. This causes the particles to bond together and form a solid structure. The sintering process also helps in enhancing the magnetic properties of the ferrite material.

5. Machining: After sintering, the rotor is machined to achieve the final dimensions and shape required for the specific motor or generator application. This may involve cutting, drilling, and grinding processes.

6. Magnetization: The final step in the production of a ferrite magnet rotor is magnetization. The rotor is exposed to a strong magnetic field, which aligns the magnetic domains within the material, resulting in the creation of a Permanent Magnet.

Once the production process is complete, the ferrite magnet rotor can be assembled into an electric motor or generator, where it plays a crucial role in generating the necessary magnetic field for the device's operation.

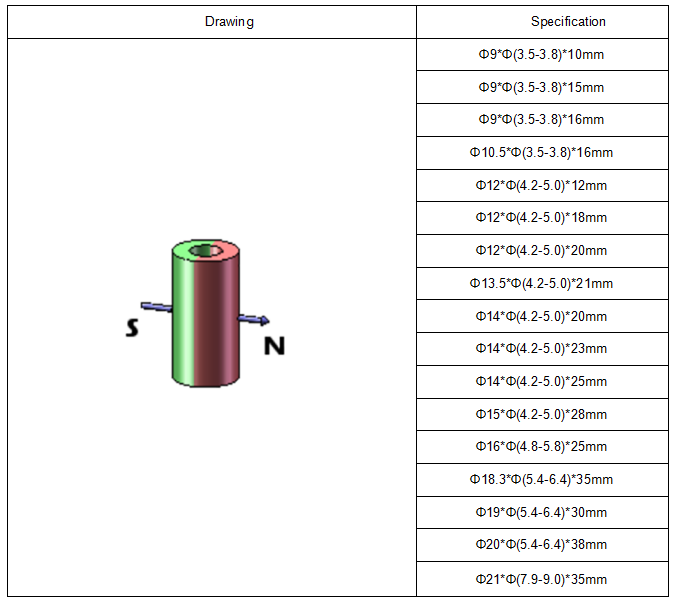

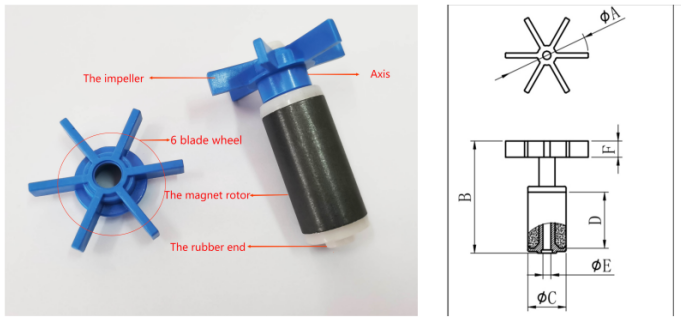

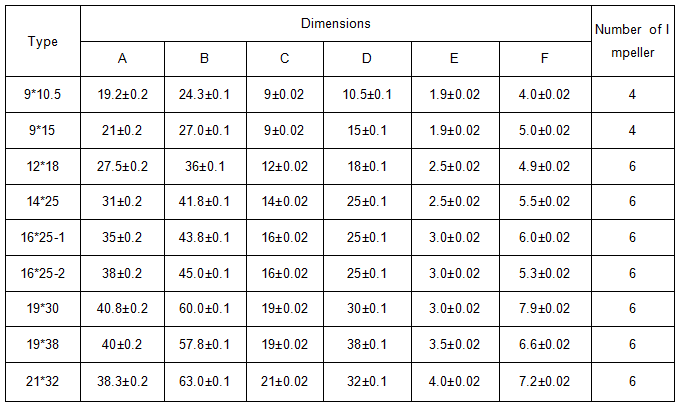

Anisotropic Ferrite Magnet Rotor,Impeller Assembly Magnet Rotor,Permanent Magnet Rotor