Payment Type:T/T,Others

Incoterm:FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery

Transportation:Ocean,Land,Air,Express,Others

Port:Guangzhou,Shenzhen,Ningbo

$0.0210000-99999Piece/Pieces

$0.01≥100000Piece/Pieces

Brand: YB

Place Of Origin: China

Species: Permanent

Composition: Rare Earth Magnet, Ferrite Magnet, Neodymium Magnet, Plastic Magnet, Ndfeb Magnet, Alnico Magnet, Rubber Magnet

Shape: Ball, Coil, Block, Cup Shape, Strip, Stick, Bar, Pot / Cup Shape, Sheet

Application: Industrial Magnet

Tolerance: ±1%

Processing Service: Bending, Welding, Decoiling, Cutting, Punching, Moulding

Product Name: Ferrite Magnet Black

Material Grade: Y10T,Y25,Y30,Y30BH,Y35

Type: Permanent

Working Temperature: 80-250℃

Quality Certificates: ISO9001

Certificates: CE,ROHS,MSDS

Delivery Time: 7-15 days

Packaging: carton package and then packed in pallets

Productivity: 30000000pcs per month

Transportation: Ocean,Land,Air,Express,Others

Place of Origin: China

Supply Ability: 30000000pcs per month

Certificate: ISO9001

HS Code: 8505190090

Port: Guangzhou,Shenzhen,Ningbo

Payment Type: T/T,Others

Incoterm: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery

What's Ferrite Magnet?

A ferrite magnet is a type of Permanent Magnet made from a composite material called ferrite, which is a mixture of iron oxide (Fe3O4) and other metallic elements such as strontium or barium. It is also known as a Ceramic Magnet due to its brittle and ceramic-like nature.

Ferrite magnets have a high resistance to demagnetization, making them suitable for various applications. They are relatively inexpensive to produce and have good magnetic properties, including high coercivity (ability to resist demagnetization) and high magnetic saturation (ability to hold a strong magnetic field).

Ferrite magnets are commonly used in various industries and applications, such as in speakers, motors, magnetic separators, magnetic resonance imaging (MRI) machines, and microwave devices. They are also used in household items like refrigerator magnets and magnetic toys.

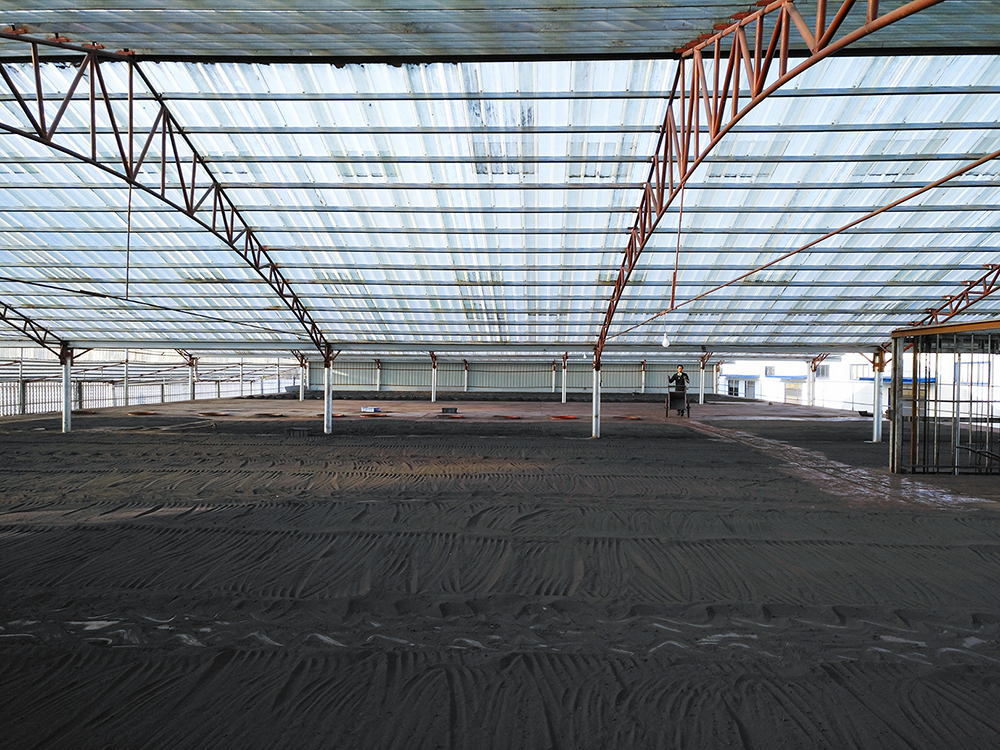

The production of Permanent Ferrite Magnet? The production of Permanent Ferrite Magnets involves several steps. Here is a general overview of the process: 1. Raw materials: The main ingredients used in ferrite magnet production are iron oxide (Fe2O3) and strontium carbonate (SrCO3) or barium carbonate (BaCO3). These materials are mixed in specific proportions according to the desired magnetic properties of the final product. 2. Mixing: The iron oxide and carbonate powders are mixed together in a ball mill or a similar grinding machine. This ensures a homogenous distribution of the particles and helps in achieving the desired magnetic properties. 3. Forming: The mixed powder is then pressed into the desired shape using a hydraulic press. The press applies high pressure to compact the powder into a solid mass. The shape can be a disc, block, or any other desired form. 4. Sintering: The formed magnets are then subjected to a high-temperature sintering process. This involves heating the pressed shapes in a furnace at temperatures ranging from 1000 to 1300 degrees Celsius. The sintering process helps in bonding the particles together and transforming the pressed shapes into a solid magnet. 5. Machining and finishing: After sintering, the magnets are machined to achieve the desired dimensions and surface finish. This can involve processes like grinding, cutting, and polishing. 6. Magnetization: The final step in the production process is magnetization. The magnets are subjected to a strong magnetic field to align the magnetic domains within the material. This ensures that the magnet exhibits a strong magnetic field in the desired direction. 7. Quality control: Throughout the production process, various quality control measures are implemented to ensure that the magnets meet the required specifications. This can include testing the magnetic properties, dimensions, and overall quality of the finished magnets. It is important to note that the specific production process may vary depending on the manufacturer and the desired magnet specifications. If you need Hard Ferrite Magnet, Disc Ferrite Magnet, Custom Anisotropic Ferrite Magnets,Custom Anisotropic Ferrite Magnets,feel free to contact us.