Payment Type:T/T,Others

Incoterm:FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery

Transportation:Ocean,Land,Air,Express,Others

Port:Guangzhou,Shenzhen,Ningbo

$0.210000-99999Piece/Pieces

$0.1≥100000Piece/Pieces

Brand: YB

Place Of Origin: China

Species: Permanent

Composition: Rare Earth Magnet, Ferrite Magnet, Neodymium Magnet, Plastic Magnet, Ndfeb Magnet, Alnico Magnet, Rubber Magnet

Shape: Ball, Coil, Block, Cup Shape, Strip, Stick, Bar, Pot / Cup Shape, Sheet

Application: Moto Magnet

Tolerance: ±1%

Processing Service: Bending, Welding, Decoiling, Cutting, Punching, Moulding

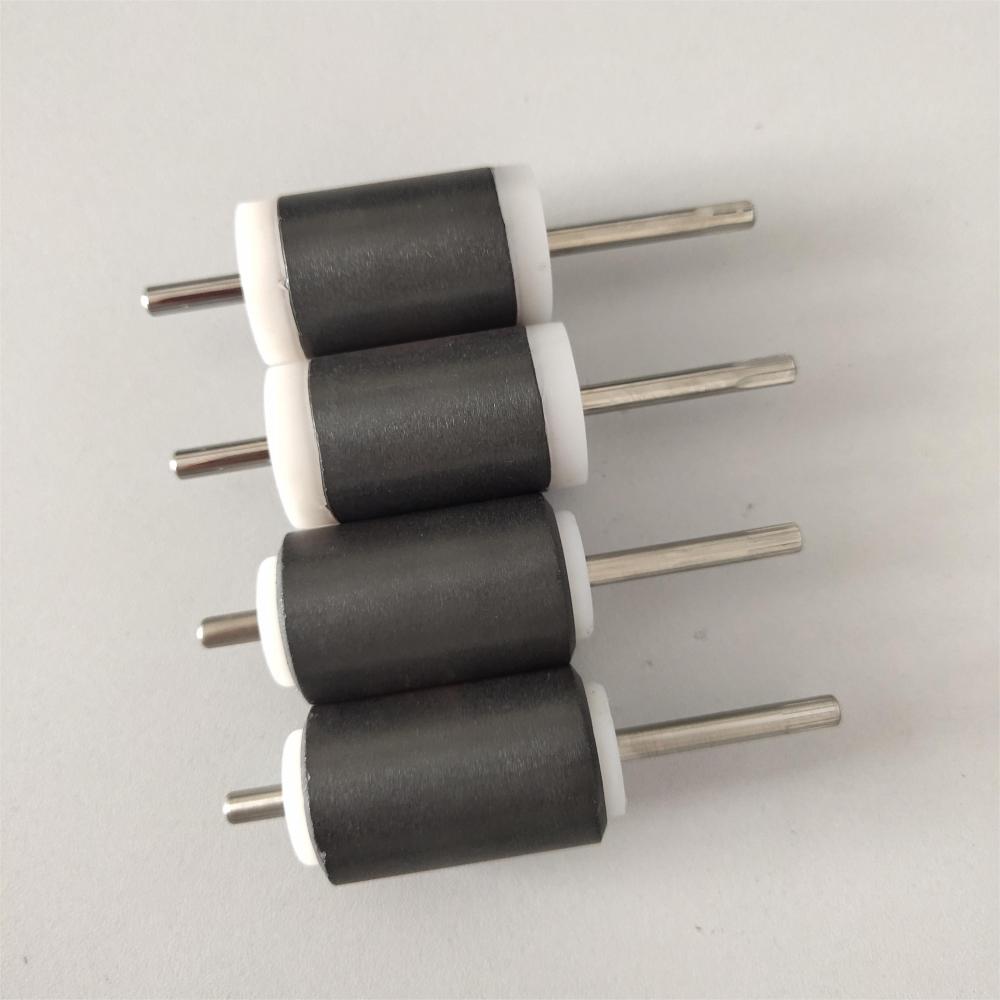

Product Name: Y30BH Ferrite Magnet Rotor

Material Grade: Y30,Y30BH,Y35

Type: Permanent

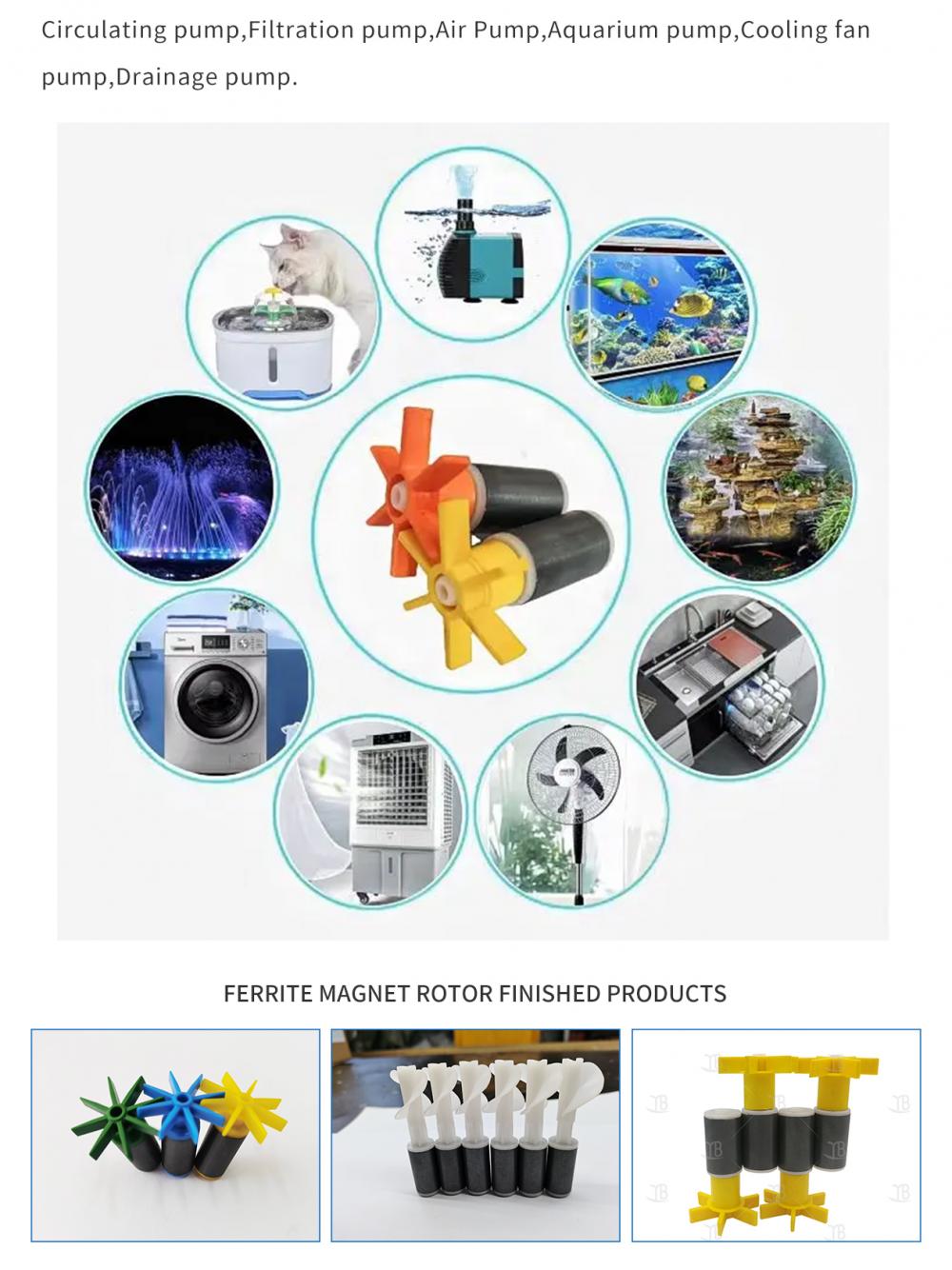

Application: water cooler pump

Working Temperature: 80-250℃

Brand: YB

Quality Certificates: ISO9001

Certificates: CE,ROHS,MSDS

Delivery Time: 7-15 working days

Packaging: Carton package and then packed in pallets

Productivity: 3000000pcs per month

Transportation: Ocean,Land,Air,Express,Others

Place of Origin: China

Supply Ability: 3000000pcs per month

Certificate: ISO9001

HS Code: 8505190090

Port: Guangzhou,Shenzhen,Ningbo

Payment Type: T/T,Others

Incoterm: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery

What's is Ferrite Magnet Rotor for conceal pump?

A Ferrite Magnet Rotor for a conceal pump refers to a type of rotor used in the construction of a pump that is designed to be concealed or hidden.

Ferrite magnets are a type of Permanent Magnet made from a mix of iron oxide and other metallic elements. They are known for their high magnetic strength and low cost, making them a popular choice for various applications, including pumps.

In the case of a conceal pump, the Ferrite Magnet Rotor is the rotating component of the pump that contains the permanent magnets. These magnets create a magnetic field that interacts with the stator (stationary part) of the pump, causing the rotor to rotate and drive the fluid being pumped.

The use of a Ferrite Magnet Rotor in a conceal pump offers several advantages, such as high efficiency, low maintenance requirements, and a compact design. Additionally, Ferrite magnets are known for their stability and resistance to demagnetization, ensuring long-term performance and reliability of the pump.

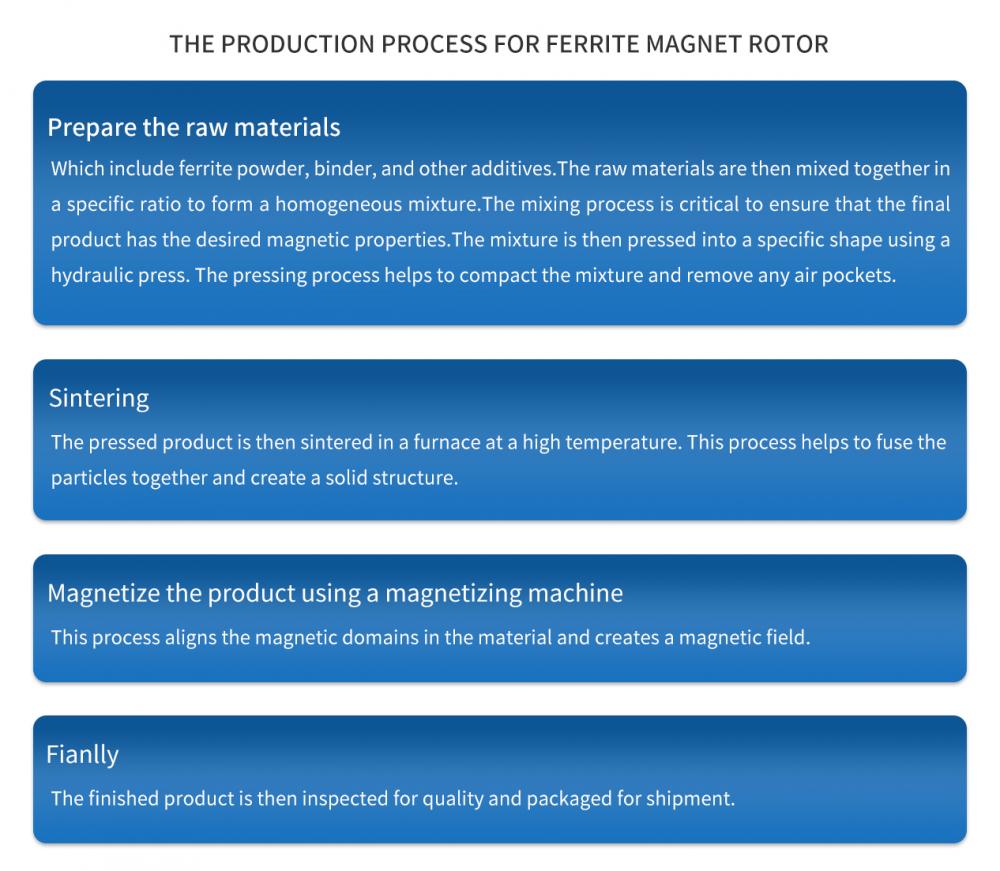

The production of ferrite magnet? The production of ferrite magnets involves several steps, including the preparation of raw materials, mixing and milling, pressing, sintering, and finishing. 1. Raw Material Preparation: The primary raw materials used in ferrite magnet production are iron oxide (Fe2O3) and strontium carbonate (SrCO3) or barium carbonate (BaCO3). These materials are carefully selected and processed to ensure high purity and consistent quality. 2. Mixing and Milling: The iron oxide and carbonate materials are mixed in precise proportions to achieve the desired magnetic properties. The mixture is then milled to a fine powder to ensure uniform distribution of the components. 3. Pressing: The powdered mixture is compacted into the desired shape using hydraulic or mechanical presses. The pressing process applies high pressure to the powder, causing it to adhere and form a solid mass known as a green compact. 4. Sintering: The green compact is then subjected to a high-temperature sintering process, typically in a controlled atmosphere furnace. During sintering, the compact is heated to a temperature below its melting point, allowing the particles to bond together and form a dense, solid structure. The sintering process also helps to enhance the magnetic properties of the material. 5. Finishing: After sintering, the magnet is cooled and undergoes various finishing processes, such as grinding, machining, and surface treatment, to achieve the desired shape, dimensions, and surface quality. The finished magnets may also be magnetized through exposure to a strong magnetic field. Throughout the production process, strict quality control measures are implemented to ensure that the ferrite magnets meet the required specifications and performance standards.