Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PRODUCTS

Product Description

what's Neodymium Magnet?

A neodymium magnet is a type of Permanent Magnet made from an alloy of neodymium, iron, and boron. It is the strongest type of permanent magnet commercially available and has a high magnetic field strength. Neodymium magnets are commonly used in various applications such as electric motors, speakers, hard drives, magnetic fasteners, and magnetic therapy devices.

The production of neodymium magnets?

The production of neodymium magnets involves several steps, including mining and refining of neodymium, alloying with other elements, and magnetization.

1. Mining and refining: Neodymium is primarily obtained from rare earth mineral deposits, such as bastnasite and monazite. These minerals are mined, and the ore is processed to separate neodymium from other elements. The refining process involves various techniques like flotation, magnetic separation, and solvent extraction.

2. Alloying: Neodymium is mixed with other elements, typically iron and boron, to form a neodymium-iron-boron (NdFeB) alloy. The alloying process involves melting the neodymium metal with the other elements in a controlled environment, such as a vacuum induction furnace. The resulting alloy has high magnetic properties.

3. Casting: The molten alloy is then cast into desired shapes, such as blocks or discs, using techniques like die casting or strip casting. The casting process helps in shaping the alloy into the desired form for further processing.

4. Machining: The cast neodymium alloy is further machined to achieve the desired dimensions and surface finish. This involves processes like cutting, grinding, and polishing. Machining is crucial to ensure the magnet's precise dimensions and smooth surface.

5. Annealing: After machining, the neodymium magnets undergo an annealing process. This involves heating the magnets to a specific temperature and then slowly cooling them to enhance their magnetic properties. Annealing helps align the magnetic domains within the magnet, increasing its strength.

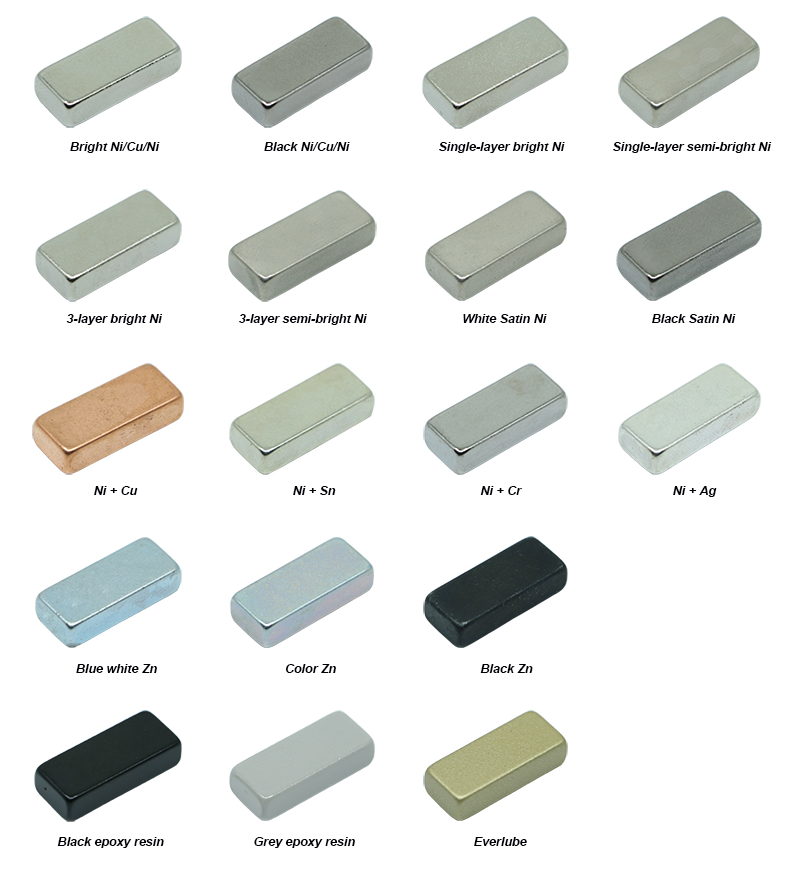

6. Coating: Neodymium magnets are often coated with protective layers to prevent corrosion and improve durability. Common coating materials include nickel, zinc, or epoxy. The coating process can involve electroplating or dip coating techniques.

7. Magnetization: The final step in neodymium magnet production is magnetization. The magnets are exposed to a strong magnetic field in a controlled manner. This aligns the magnetic domains within the magnet, resulting in a strong and consistent magnetic field.

Once the magnets are produced, they can be used in various applications, such as electric motors, generators, speakers, magnetic separators, and magnetic resonance imaging (MRI) machines.

Sintered Neodymium Mangets,Sintered Neodymium Magnet,Ceramic Ferrite Magnet

YOU MIGHT ALSO LIKE

GET IN TOUCH

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand. we’ve got preferential price and best-quality products for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.