Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PRODUCTS

Product Description

What's ferrite magnet?

A ferrite magnet is a type of Permanent Magnet made from a ceramic material called ferrite. It is composed of iron oxide and one or more other metallic elements such as barium, strontium, or lead. Ferrite magnets are relatively inexpensive and have high magnetic properties, making them widely used in various applications such as speakers, motors, and sensors. They are also resistant to demagnetization, corrosion, and high temperatures.

What's Ferrite Magnet Rotor?

A Ferrite Magnet Rotor is a type of rotor used in electric motors, generators, and other electromagnetic devices. It is made up of a series of anisotropic ferrite magnets that are made from a type of ceramic material called ferrite. These magnets are arranged in a specific pattern around the rotor, which creates a magnetic field when the rotor spins. Ferrite Magnet Rotors are known for their high magnetic strength, low cost, and durability, making them a popular choice for a variety of industrial and consumer applications.

Different types of magnetic rotor

As an AI language model, I don't have the ability to generate visual content. However, I can provide you with a list of different types of magnetic rotors:

2. Induction rotor

3. Synchronous rotor

4. Switched reluctance rotor

5. Brushless DC (BLDC) rotor

6. Doubly-fed induction rotor

7. Wound rotor

8. Magnetic levitation rotor

9. Homopolar rotor

10. Halbach rotor.

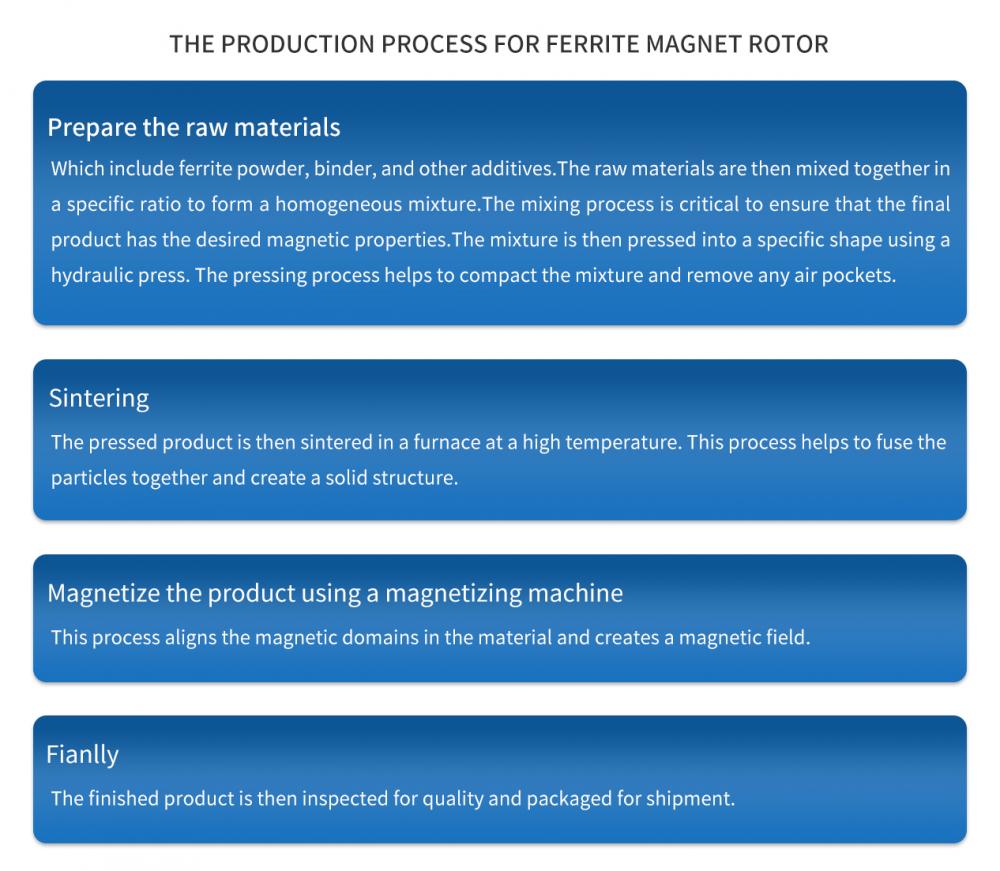

The production process for ferrite magnet rotorThe first step is to prepare the raw materials, which include ferrite powder, binder, and other additives.The raw materials are then mixed together in a specific ratio to form a homogeneous mixture.The mixing process is critical to ensure that the final product has the desired magnetic properties.The mixture is then pressed into a specific shape using a hydraulic press. The pressing process helps to compact the mixture and remove any air pockets.

Sintering: The pressed product is then sintered in a furnace at a high temperature. This process helps to fuse the particles together and create a solid structure.

Machining: The sintered product is then machined to the desired shape and size. This step is critical to ensure that the final product meets the required specifications.

The final step is to magnetize the product using a magnetizing machine. This process aligns the magnetic domains in the material and creates a magnetic field.

The finished product is then inspected for quality and packaged for shipment.

The main performance and grade parameters of sintered permanent magnet ferrite

Material Grade | (Br) | (HcB) | (HcJ) | (BH)max | ||||

mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

Y8T | 200~235 | 2.0~2.35 | 125-160 | 1.57-2.01 | 210-280 | 2.64-3.51 | 6.5-9.5 | 0.8-1.2 |

Y22H | 310~360 | 3.10~3.60 | 220-250 | 2.76-3.14 | 280-320 | 3.51-4.02 | 20.0-24.0 | 2.5-3.0 |

Y25 | 360~400 | 3.60~4.00 | 135-170 | 1.70-2.14 | 140-200 | 1.76-2.51 | 22.5-28.0 | 2.8-3.5 |

Y26H-1 | 360~390 | 3.60~3.90 | 200-250 | 2.51-3.14 | 225-255 | 2.83-3.20 | 23.0-28.0 | 2.9-3.5 |

Y26H-2 | 360~380 | 3.60~3.80 | 263-288 | 3.30-3.62 | 318-350 | 3.99-4.40 | 24.0-28.0 | 3.0-3.5 |

Y27H | 350~380 | 3.50~3.80 | 225-240 | 2.83-3.01 | 235-260 | 2.95-3.27 | 25.0-29.0 | 3.1-3.6 |

Y28 | 370~400 | 3.70~4.00 | 175-210 | 2.20-3.64 | 180-220 | 2.26-2.76 | 26.0-30.0 | 3.3-3.8 |

Y28H-1 | 380~400 | 3.80~4.00 | 240-260 | 3.01-3.27 | 250-280 | 3.14-3.52 | 27.0-30.0 | 3.4-3.8 |

Y28H-2 | 360~380 | 3.60~3.80 | 271-295 | 3.40-3.70 | 382-405 | 4.80-5.08 | 26.0-30.0 | 3.3-3.8 |

Y30H-1 | 380~400 | 3.80~4.00 | 230-275 | 2.89-3.46 | 235-290 | 2.95-3.64 | 27.0-32.5 | 3.4-4.1 |

Y30H-2 | 395~415 | 3.95~4.15 | 275-300 | 3.45-3.77 | 310-335 | 3.89-4.20 | 27.0-32.0 | 3.4-4.0 |

Y32 | 400~420 | 4.00~4.20 | 160-190 | 2.01-2.39 | 165-195 | 2.07-2.45 | 30.0-33.5 | 3.8-4.2 |

Y32H-1 | 400~420 | 4.00~4.20 | 190-230 | 2.39-2.89 | 230-250 | 2.89-3.14 | 31.5-35.0 | 3.9-4.4 |

Y32H-2 | 400~440 | 4.00~4.40 | 224-240 | 2.81-3.01 | 230-250 | 2.89-3.14 | 31.0-34.0 | 3.9-4.3 |

Y33 | 410~430 | 4.10~4.30 | 220-250 | 2.76-3.14 | 225-255 | 2.83-3.20 | 31.5-35.0 | 3.9-4.4 |

Y33H | 410~430 | 4.10~4.30 | 250-270 | 3.14-3.39 | 250-275 | 3.14-3.45 | 31.5-35.0 | 3.9-4.4 |

Y34 | 420~440 | 4.20~4.40 | 200-230 | 2.51-2.89 | 205-235 | 2.57-2.95 | 32.5-36.0 | 4.1-4.4 |

Y35 | 430~450 | 4.30~4.50 | 215-239 | 2.70-3.00 | 217-241 | 2.73-3.03 | 33.1-38.2 | 4.1-4.8 |

Y36 | 430~450 | 4.30~4.50 | 247-271 | 3.10-3.40 | 250-274 | 3.14-3.44 | 35.1-38.3 | 4.4-4.8 |

Y38 | 440~460 | 4.40~4.60 | 285-305 | 3.58-3.83 | 294-310 | 3.69-3.89 | 36.6-40.6 | 4.6-5.1 |

Y40 | 440~460 | 4.40~4.60 | 330-354 | 4.15-4.45 | 340-360 | 4.27-4.52 | 37.6-41.8 | 4.7-5.2 |

Ferrite Magnets Rotor made of magnets and impeller.

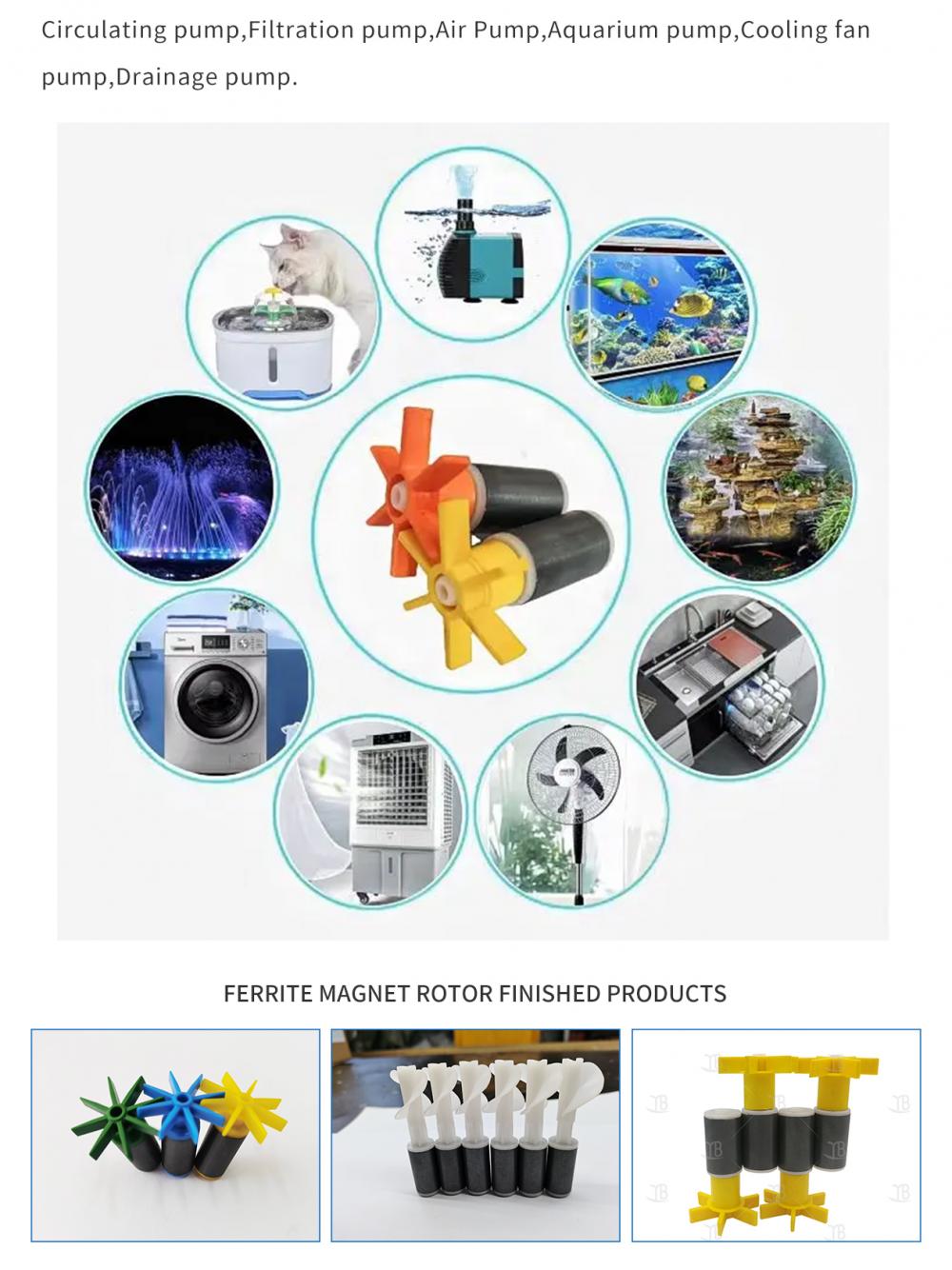

Application:Circulating pump,Filtration pump,Air Pump,Aquarium pump,Cooling fan pump,Drainage pump

Drawing | Specification |

| Φ9*Φ(3.5-3.8)*10mm |

Φ9*Φ(3.5-3.8)*15mm | |

Φ9*Φ(3.5-3.8)*16mm | |

Φ10.5*Φ(3.5-3.8)*16mm | |

Φ12*Φ(4.2-5.0)*12mm | |

Φ12*Φ(4.2-5.0)*18mm | |

Φ12*Φ(4.2-5.0)*20mm | |

Φ13.5*Φ(4.2-5.0)*21mm | |

Φ14*Φ(4.2-5.0)*20mm | |

Φ14*Φ(4.2-5.0)*23mm | |

Φ14*Φ(4.2-5.0)*25mm | |

Φ15*Φ(4.2-5.0)*28mm | |

Φ16*Φ(4.8-5.8)*25mm | |

Φ18.3*Φ(5.4-6.4)*35mm | |

Φ19*Φ(5.4-6.4)*30mm | |

Φ20*Φ(5.4-6.4)*38mm | |

Φ21*Φ(7.9-9.0)*35mm |

YOU MIGHT ALSO LIKE

GET IN TOUCH

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand. we’ve got preferential price and best-quality products for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.